Laser Welding Services in Chennai, Kancheepuram, Vallam, and Oragadam

Introduction to Laser Welding Services

Vijay Laser offers specialized laser welding services across Chennai, Kancheepuram, Vallam, and Oragadam, catering to diverse industrial needs. Our expertise lies in precision welding techniques that ensure the durability and functionality of critical components such as moulds and dies.

Overview of Laser Welding Technique

Laser welding involves the addition of filler material between worn or damaged surface areas of moulds and dies. This technique melts the mother material, yielding a built-up surface slightly higher than the original part dimensions. At Vijay Laser, we employ both manual and automated modes based on specific requirements.

Manual Welding Process

In manual welding, skilled technicians manually handle the filler wire, ensuring intimate contact with the mould material. This method, though slower, is highly effective and suitable for intricate repairs that demand a high level of precision.

Automated Welding Process

For enhanced efficiency and consistency, we utilize an automated filler wire feed system integrated with pulsed Nd: YAG laser welding systems. This advanced setup significantly increases welding speed and reduces the skill level required, making it ideal for complex mould repair projects.

Applications and Repaired Locations

Our laser welding services are extensively used for repairing various mould and die components, including:

Corners

Both outside and inside corners

Core and Cavities

Repairing damages in core and cavity areas

Sliders and Inserts

Ensuring smooth functionality of sliders and inserts

Materials Handled

We specialize in welding a wide range of materials, including:

410 SS

420 SS

440 SS

Beryllium Copper

Aluminium

D2, A2, M2

S7, P20

Stavax

NAK 55

QRO 90

H-13

Competitive Advantages

Choosing Vijay Laser for your laser welding needs offers several competitive advantages:

Minimal

Heat Input

Ensures minimal distortion to precision in the weld area.

Precise

Control

Allows welding close to sensitive features without disturbance.

Minimal Discoloration

Maintains the aesthetic integrity of the base material.

Minimal Weld Metal Deposition

Reduces the need for extensive machining to restore original dimensions.

Hard and Tough Weld Metal

Attributes to a fine grain structure, ensuring durability.g

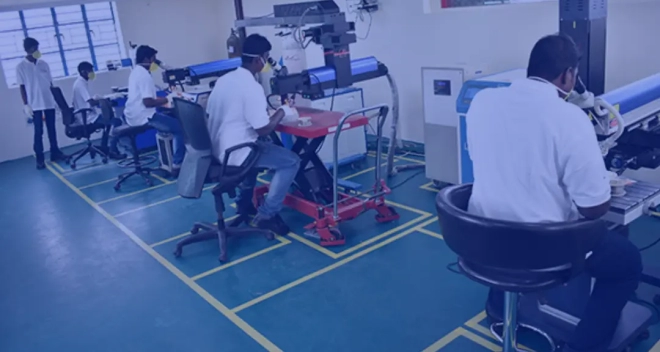

Facilities and Capabilities

Handling Capacity

Capable of handling moulds and dies up to 5 tons.

Specialized Texturing Rods

Used exclusively for welding in texturing areas of moulds.

Onsite Services

Available based on company requisition, ensuring convenience and efficiency.

Vijay Laser stands as a premier provider of laser welding services in Chennai, Kancheepuram, Vallam, and Oragadam, offering unmatched expertise and technological capabilities. Whether you require precision repairs for moulds, dies, or other critical components, our team is committed to delivering superior quality and reliability.

For more information on our laser welding services or to discuss your specific requirements, contact Vijay Laser today. Let us partner with you to enhance the performance and longevity of your industrial assets. Check our other services