TIG Welding Services in Chennai, Kancheepuram, Vallam, and Oragadam

Introduction

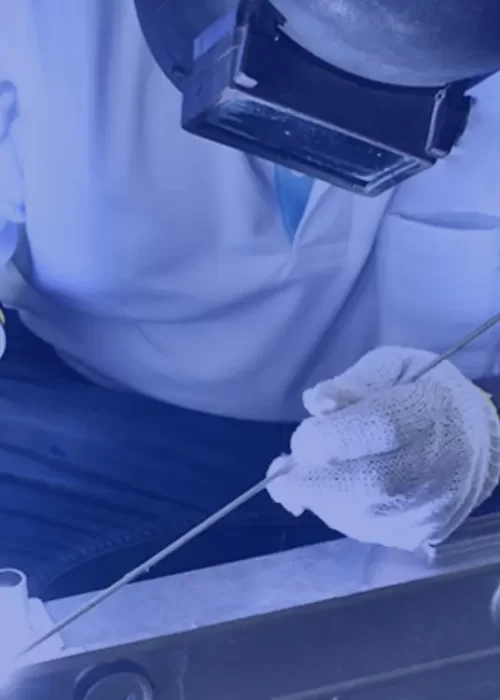

Tungsten Inert Gas welding is a precise welding process that utilizes a non-consumable tungsten electrode and an inert shielding gas, typically argon. This method is renowned for its ability to provide concentrated heating and effective protection of the weld pool, resulting in high-quality welds.

How it Works

It involves the following key elements:

Shielding Gas: Usually argon, to protect the weld area from atmospheric contamination.

Tungsten Electrode: Non-consumable electrode that generates the arc and remains intact during welding.

Clean Surface: Essential to remove oxide build-up, ensuring proper fusion of metals.

Applications

It is widely used for its precision and versatility, including:

Concentrated Heating

Provides localized heating of the workpiece, ideal for welding thin materials or intricate joints.

Effective Shielding

Uses inert shielding gas to protect the weld pool, reducing oxidation and ensuring clean welds.

Independent of Filler Material

Can be performed without filler material, depending on the application requirements.

Minimal Preparation

Filler materials require less preparation if alloy compatibility is ensured.

No After Treatment

Produces clean welds with no slag or spatter, minimizing post-welding cleanup.

Accessibility

Capable of welding in tight or difficult-to-reach areas.

Materials Handled

Vijay Laser specializes on a variety of materials, including:

Metals

Steel, Stainless Steel, Aluminium, Copper, Brass, Titanium, etc.

Alloys

Various alloys used in industrial applications.

Industrial Usages

It serves critical roles in multiple industries:

Manufacturing

Precision welding for parts and components requiring high-quality finishes.

Automotive

Precision welding for parts and components requiring high-quality finishes.

Aerospace

Welding of aircraft components where strength and precision are paramount.

Medical

Welding of surgical instruments and equipment.

Competitive Advantages of TIG Welding

Competitive Advantages of TIG Welding

Choosing TIG welding offers several competitive advantages:

High Quality

Produces strong, clean welds suitable for critical applications.

Versatility

Accommodates various materials and thicknesses with precise control.

No Contamination

Shields welds from atmospheric contaminants, ensuring purity.

Cost Efficiency

Reduces material waste and post-welding cleanup efforts.

Durability

Creates durable welds with minimal distortion and heat-affected zones.

Facilities and Capabilities

State-of-the-art Equipment

Utilizing advanced TIG welding machines and accessories.

Skilled Technicians

Expertise in handling complex welding projects with precision.

Onsite Services

Available as per client needs for convenience and efficiency.

Vijay Laser stands as a leading provider of TIG welding services in Chennai, Kancheepuram, Vallam, and Oragadam, offering superior quality and reliability. Whether you require precise welding for industrial, automotive, aerospace, or medical applications, our team is committed to delivering excellence.

For more information on our TIG welding services or to discuss your specific requirements, contact Vijay Laser today. Let us partner with you to achieve optimal welding solutions for your business needs. Check our other services.